“Why can’t I print the things I want”, a sentence which Mo’men thought about over and over since his childhood. He always dreamed of printing on T-shirts, which wasn’t popular at that time, and the clothing market had become popular.

“I wanted to be productive, instead of wasting my time in the holiday”, this is what filled Malak’s mind as she wanted to make use of her summer holiday.

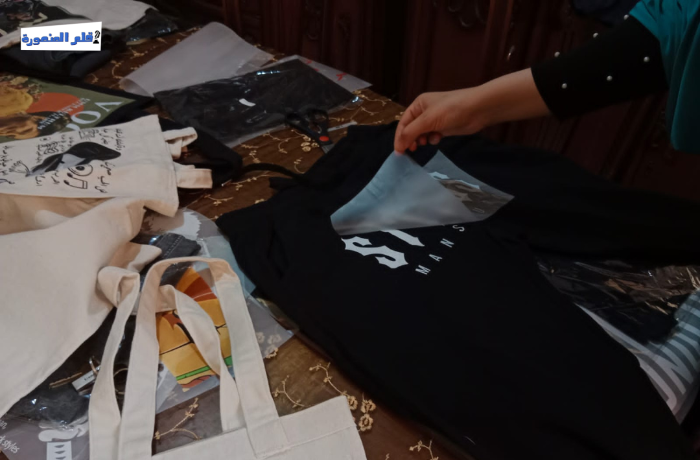

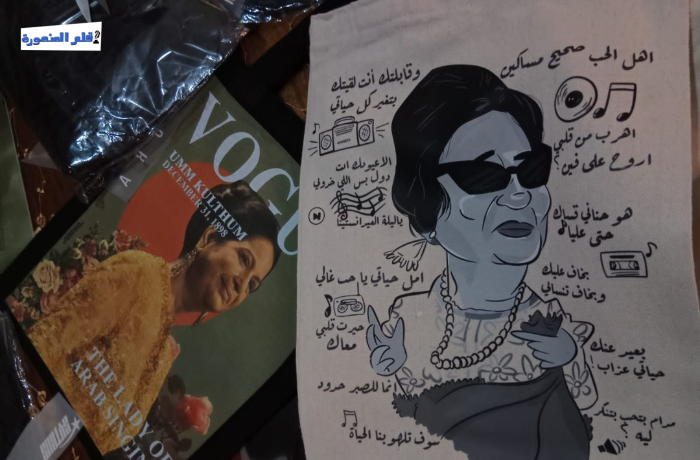

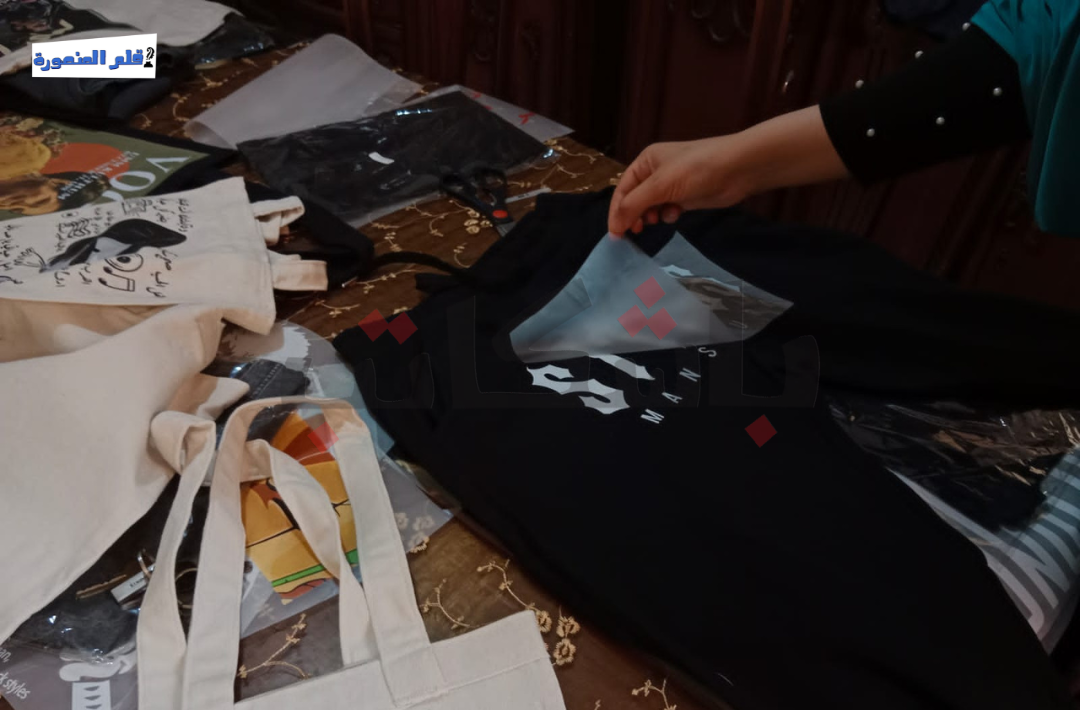

Mo’men Moheb, a high school student specialising in science and mathematics, began his T-shirt printing business a year and a half ago. His sister, Malak Moheb, a first-year high school student, joined him by starting her own project of printing “Tote Bags,” which are linen fabric bags measuring 30 x 40 cm, with some designs featuring pockets.

Malak launched her project to sell “Tote Bags” due to their popularity and people’s fondness for using them in daily life. They live in Talkha city, where their business started, and they operate from home.

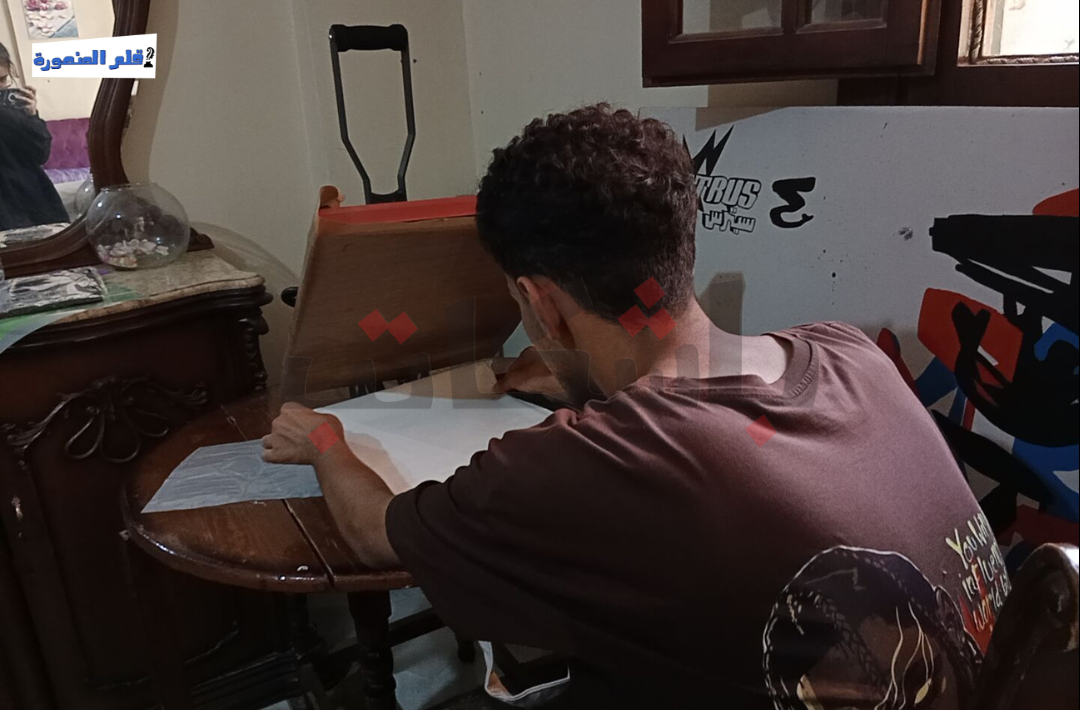

Mo’men Moheb explains that he initiated his project with the idea of collaborating with his friends and leveraging their talents. The concept emerged during his first-year high school holiday, “I felt the need to do something productive.” Mo’men adds that he is a designer, he has been passionate about creating designs since childhood. He enjoyed making posters of his favourite cartoons like “Spiderman” and “Lightning McQueen”.

Eventually, he shifted to designing clothing prints particularly, because the clothing market was booming, and he noticed a lack of designs for rap music fans “which is a kind of Hip Hop music”.

Mo’men adds, “people often find attractive designs in expensive stores and companies, so they come to me requesting similar designs.”

He also added that starting the project was not costly for him, as he used 800 EGP he received as a special Eid treat (Eidyya). This was his first personal venture, leading him to create the “Sytrus Store” page on Instagram.

“I managed with order and perseverance to fulfil my dream, growing every day,” continued Mo’men.

Mo’men says that his family and friends are his greatest supporters. After graduating from high school, he plans to open his own shop and purchase a “DTF” printing machine, despite its high cost of over half a million pounds. He believes he can grow his business and afford it.

The machine, which Mo’men noted for its big size, connects to a laptop, where designs are uploaded in a specific format, and the design length is set in metres.

He explained that he uses a heat press and butter paper to transfer the printed design onto the T-shirt, ensuring the design doesn’t burn or peel off. Currently, he collaborates with a printing press that uses this machine. The key advantage of this printing method is its high quality and durability, as it prevents peeling and can print any design. However, some machines have limitations regarding colour and space.

He prepares the design on his laptop, measures it on the T-shirt, prints and cuts the design, and then presses it onto the T-shirt, which he orders from the factory.

Mo’men mentioned that the biggest challenge in the T-shirt business is the competition, as many people are working on similar projects. To stand out, he strives to be unique.

He handles all aspects of the work himself, from designing and preparing the files to ordering T-shirts from a factory in Cairo and printing them. Although this process is time-consuming, it saves him money, “if I hired another designer, it would cost a lot of money”, noting that the printing prices he works with start at 180 EGP per metre.

Regarding studying, Mo’men commented, “the most difficult thing for me was handling my work during exams.” As a high school student, he finds it challenging to balance his class and work schedules. To manage, he sacrifices his time with friends on Fridays to focus on his project, a routine he plans to maintain until December.

After that, with the increased pressure of high school, he intends to hire a designer who shares his energy and passion to take over the work.

Mo’men wrapped up by saying, “I won’t leave this page until I’ve created another one,” emphasising that he cannot ignore his studies.

Malak Moheb mentioned that she had been contemplating starting her project since last year at school, “I wanted to do something productive during the holiday.” Creating Tote bags was a unique idea as they’re not widely available online in Mansoura. These bags are practical for carrying books and laptops. She decided to offer custom prints, allowing customers to choose any design they wanted, which is not an option in stores. Consequently, Malak launched the “Cordelia Store” page on Instagram to showcase her products.

Malak uses DTF printing, which, despite being expensive, is of high quality and thus suitable for her customers. She gets the tote bags from a factory in Mahalla, and they are delivered to her in bulk by a shipping company for printing.

Malak said that, despite her young age “the project is no longer difficult, but it requires someone responsible and passionate.” She added that her friends and family are her greatest supporters. The initial capital for her project, which was 1,000 EGP, she received from her father to purchase materials, including her project cards. She has since continued her work using her own profits.

“I design the collection, upload it, and whenever I receive an order from the factory, I prepare the bags, press, package, and get them ready for the courier to deliver.”

Among the challenges Malak encounters is the uncertainty about whether the order will be received, also the stress from not adjusting the design size on the bags, or delays in order dates.

Malak mentioned that her future plans are not directly related to her project. She hopes to have an independent job and life, while continuing the project alongside and introducing new products to her store.

She sets a daily schedule between work, studying, and the gym.

Malak and Mo’men, both use couriers for deliveries, while they meet friends and family to give them the products they asked for.