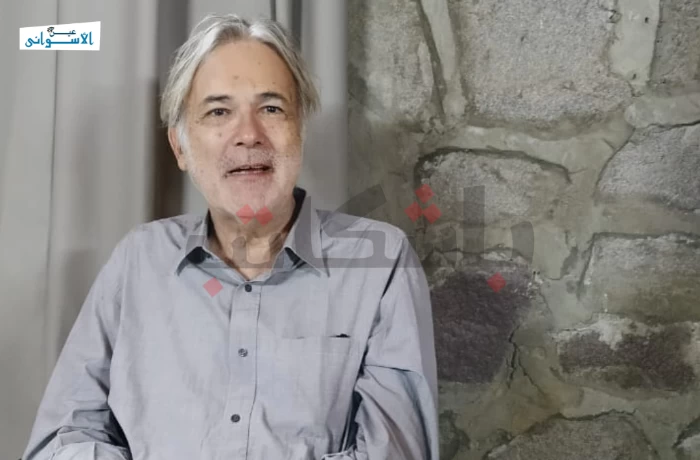

In the Sheikh Haroun neighbourhood, you’ll find Mahmoud Attallah’s home. Through his open door, passers-by can spot him seated on the floor, diligently preparing trays of Kahk (cookies). Mahmoud has been carrying out this tradition at the end of every Ramadan, just before the Al-Fitr feast, for the past 40 years.

Since the 1970s, 70-year-old Mahmoud Attallah has transformed his home into a workshop for crafting Kahk trays. He mastered this trade from the market and has continued it on his own ever since.

Mahmoud recounts that he initially flitted between various trades; he began as a cobbler, then transitioned to sculpting statues for tourists in a granite workshop, where he still works to this day. Throughout the year, he also crafts Kahk trays to order, particularly for feasts and weddings.

Attallah sources the tin from grocers when available, or the customer provides the necessary amount for the order. “Tin isn’t as readily available as it once was; people used to discard it and give it to me for free. Nowadays, it’s harder to come by, and I have to purchase it—initially at 5 EGP per tin can, and now for 20 EGP.”

Kahk Tray from Ghee Tin Can

To craft a tin tray for Kahk, the craftsman repurposes tin cans originally used for storing ghee, salted fish, or molasses, available in various sizes. One tin can yields either two large trays or four small ones.

In the foyer of his home, Attallah employs a metal rod and hammer to transform tin cans into trays. He starts by removing the top and bottom of the can and filing down the sharp edges. After folding the can, he uses scissors to cut it into two or four pieces, depending on the customer’s request. Then, placing the tin piece on a sturdy metal surface, he hammers it until it is as smooth and flat as paper.

Then comes the pre-final stage; preparing the sides of the tray. Using a fixed base, Attallah places the tin piece and folds the four sides after trimming a small triangular section from each corner.

Over Hammering Ruins the Tin

Attallah proceeds with the final stages of finishing the tray, “I start by hammering the sides of the tin to ensure they are parallel, and then fold the upper part of the sides to smooth the edges, preventing any harm to the user. This is the most challenging stage, as over-hammering can render the tin unusable or puncture it. However, with years of practice and experience, this task has become simple and error-free.”

It takes Attallah 15 minutes to finish turning a single tin can into a tray, which he sells for 10 to 30 EGP, depending on the size and number of trays.

The final stage is carried out by the customer, who takes the tray to a local bakery. There, it is fired in an oven until it turns black, ensuring it can be used for baking Kahk without burning or altering the taste for many years.